Choosing the right warehouse is one of the key decisions that affect the operational efficiency of your business. Proper management of warehouse space, lead times and storage costs can determine the success of the entire organization. In an era of increasing competition and customer expectations, companies are looking for more and more innovative solutions to streamline their logistics processes while reducing costs.

One of the most effective approaches gaining popularity among companies in need of warehouse services is Lean Logistics. By implementing Lean principles, warehouses become not only more efficient, but also more flexible and resilient to changing market conditions. How exactly does this work, and why should you consider choosing a warehouse guided by this philosophy? Find the answers to these questions in the following sections of the article.

What is Lean Logistics, and How Does it Change Warehouse Management?

Lean logistics is an approach that is revolutionizing the way warehouses and supply chains are managed. Originating in Japan, this philosophy gained popularity with Toyota, which applied it to manufacturing. Today, Lean logistics is not just a strategy for improving efficiency, but a way of thinking that changes the perspective on what logistics should look like in a modern company. Its goal is to eliminate all kinds of “waste” – from excess inventory to unnecessary activities to suboptimal processes.

It allows businesses to minimize costs, speed up lead times and at the same time provide higher quality service. In practice, Lean logistics in warehousing means not only better organization of space, but also implementation of innovative technologies that allow smoother flow of goods and more precise forecasting of demand.

How does the Lean Logistics approach translate into quality customer service?

1 Reduce lead times:

Lean Logistics focuses on eliminating “waste,” leading to streamlined warehouse processes. Faster order fulfillment is a key element affecting customer satisfaction. By optimizing the flow of goods, the warehouse is able to prepare orders for shipment faster, resulting in shorter customer wait times.

2 Accuracy and error minimization:

Lean allows for increased precision in the order picking process, as the methodology eliminates unnecessary steps that can lead to mistakes. Fewer errors translate into more satisfied customers, who receive exactly what they ordered, in a timely manner.

3 Better communication and transparency:

Lean Logistics implements strategies that allow easier access to information about order status, inventory levels or delivery times. This gives the customer a sense that the company is operating efficiently and can count on reliable service.

Does your current warehouse meet Lean standards? – A quick checklist from LCL Logistic

✅ Efficient use of warehouse space

Is your current warehouse making the most of the available space? Excess inventory can cause chaos and increase costs. At LCL Logistic warehouses, every square meter is optimized to ensure quick access to goods and efficient logistics.

✅ Ease of navigation and space organization

Does your warehouse layout support efficient logistics? Proper signage, the FIFO (First In, First Out) principle, and logically arranged storage areas are key to faster order fulfillment. Our structure offers modern warehouses designed in accordance with Lean best practices.

✅ Minimizing inventory

Are you storing only what you actually need? Excess inventory takes up space and generates additional costs. Our warehouses operate according to the “Just-in-Time” method, helping you maintain optimal inventory levels and reduce storage costs.

✅ Optimizing your warehouse processes

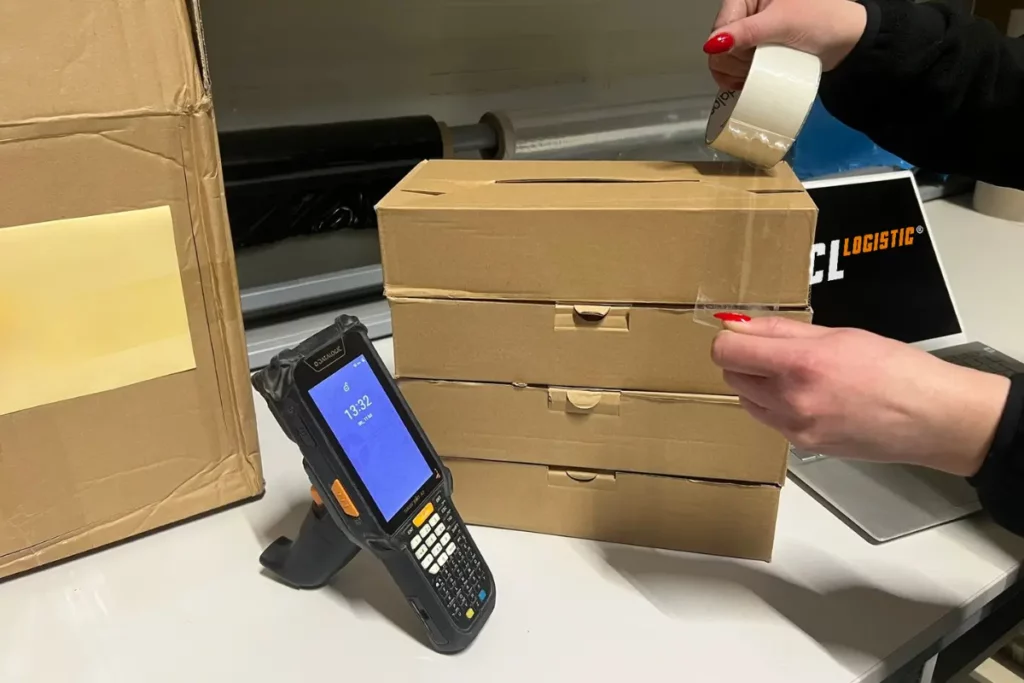

Are your logistics processes free of unnecessary delays and inefficiencies? At our company, we use Lean solutions that eliminate unnecessary movements, reduce order picking times and streamline the flow of goods. As a result, you can be sure that your logistics is running smoothly and your processes are running smoothly.

✅ Optimal order processing time

Does your warehouse allow you to process orders quickly and on time? If the waiting time for goods to be shipped is too long, it can affect your customers’ satisfaction, and we at LCL Logistic make sure that your orders are processed as quickly as possible.

✅ Minimizing errors

Do current warehouse procedures eliminate mistakes? Incorrect labeling, clutter and lack of automation increase the risk of errors. We use proven solutions in our warehouses to reduce mistakes and improve service quality.

✅ Using modern warehouse management tools (WMS).

Are you using modern warehouse management systems? LCL Logistic uses advanced WMS systems to automate inventory management, speed up order processing, and provide full control over logistics processes.

Summary: LCL Logistic – your partner in Lean Logistics compliant warehousing

The Lean Logistics approach is changing the way we think about warehouse management. It emphasizes the elimination of unnecessary processes, reduction of waste and efficient use of space. Thus, the use of modern tools, such as WMS systems, makes warehouses more flexible, faster to adapt to market changes and more effective in responding to growing customer needs. By implementing these principles in your warehouses, LCL Logistic will help you achieve better operational efficiency and full control over logistics processes, which will affect your long-term success.